|

The Gasket |

|

|

The

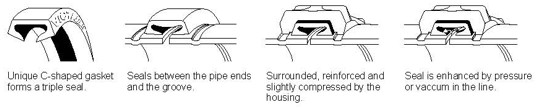

grooved piping concept is simple and reliable. The coupling housing

performs several functions as an integral part of the pipe joint.

It contains the gasket, which is fully enclosed, reinforcing and

securing it in position for proper sealing. The housing also engages

on the pipe around the full pipe circumference and creates a unified

joint while providing the advantages of mechanical joining. |

|

Gasket selection |

Victaulic

offers a variety of synthetic rubber gaskets/o-rings to provide

the option of grooved piping products for the widest range of

applications. To assure the maximum life for the service intended,

proper gasket selection and specification in ordering is essential. Potable Water Grade

“E” EPDM, Grade “E” Vic-Plus™, Grade “EHP” and Grade “EHP” Vic-Plus

gaskets were submitted to Underwriters’ Laboratories Inc. for

evaluation in potable water applications. EPDM material was tested

to the requirements of ANSI/NSF 61 (Drinking Water System Components

- Health Effects). Successful completion of this testing allows

us to state that our EPDM gasket material is UL classified in

accordance with ANSI/NSF 61 for cold (+86°F/+30°C) and

hot (+180°F/+82°C) potable water service. |

|

Standard gaskets |

| |

|

|

|

|

| |

to +110°C |

|

Stripe |

Recommended for hot water service within the speci-fied temperature range plus a variety of dilute acids, oil-free air and many chemical services. UL classified in accordance with ANSI/NSF 61 for cold +86°F/+30°C and hot +180°F/+82°C potable water service. NOT RECOMMENDED FOR PETROLEUM SERVICES. |

| |

to +120°C |

|

Stripe |

Recommended for hot water service within the specified temperature range. UL classified in accor-dance with ANSI/NSF 61 for cold +86°F/+30°C and hot +180°F/+82°C potable water service. NOT RECOMMENDED FOR PETROLEUM SERVICES. |

| |

to +82°C |

|

Stripe |

Recommended for petroleum products, hydrocar-bons, air with oil vapors, vegetable and mineral oils within the specified temperature range; not recom-mended for hot dry air over +140°F/+60°C and water over +150°F/+66°C. NOT RECOMMENDED FOR HOT WATER SERVICES. |

| (Type-A) |

|

|

Stripe |

Applicable for wet and dry (oil-free air) sprinkler services only. For dry services, Victaulic continues to recommend the use of FlushSeal® gaskets. NOT RECOMMENDED FOR HOT WATER SERVICES. |

|

Special gaskets |

| |

|

|

|

|

| |

to +71°C |

hydrin |

Stripe |

Specially compounded to provide superior service for common aromatic fuels at low temperatures. Also suitable for certain ambient temperature water services. |

| |

to +82°C |

|

Stripe |

RRecommended for hot lubricating oils and certain chemicals. Good oxidation resistance. Will not sup-port combustion. |

| |

to +149°C |

elastomer |

Stripe |

Recommended for many oxidizing acids, petroleum oils, halogenated hydrocarbons, lubricants, hydraulic fluids, organic liquids and air with hydrocarbons to +300°F/+149°C. NOT RECOMMENDED FOR HOT WATER SERVICES. |

| |

to +177°C |

|

Gasket |

Recommended for dry heat, air without hydro-carbons to +350°F/+177°C and certain chemical services. |

| |

to +82°C |

|

Gasket |

No carbon black content. May be used for food. Meets FDA requirements. Conforms to CFR Title 21 Part 177.2600. Not recommended for hot water services over +150°F/+66°C or for hot, dry air over +140°F/+60°C. NOT RECOMMENDED FOR HOT WATER SERVICES. |

| EndSeal |

to +66°C |

|

External Identifi- cation |

Specially compounded with excellent oil resistance and a high modulus for resistance to extrusion. Temperature Range –20°F/–29°C to +150°F/+66°C. Recommended for petroleum products, air with oil vapors, vegetable and mineral oils within the speci-fied temperature range. Not recommended for hot water services over +150°F/+66°C or for hot, dry air over +140°F/+60°C. For maximum gasket life under pressure extremes, temperature should be limited to +120°F/+49°C. |

| |

to +110°C |

|

|

Recommended for hot water service within the specified temperature range plus a variety of dilute acids, oil-free air and many chemical services. DVGW, KTW, ÖVGW, and SVGW approved for W534, EN681-1 Type WA cold potable water service up to +122°F/+50°C. NOT RECOMMENDED FOR PETROLEUM SERVICES |

| |

to +40°C |

|

|

Recommended for potable water service within the specified temperature range plus a variety of dilute acids, oil-free air and many chemical services. French ACS (Crecep) approved for EN681-1 Type WA cold potable water service. NOT RECOMMENDED FOR PETROLEUM SERVICES |

For specific services refer to publication Gasket Selection Guide.pdf and Gasket Chemical Services Guide - Long Report